Loading

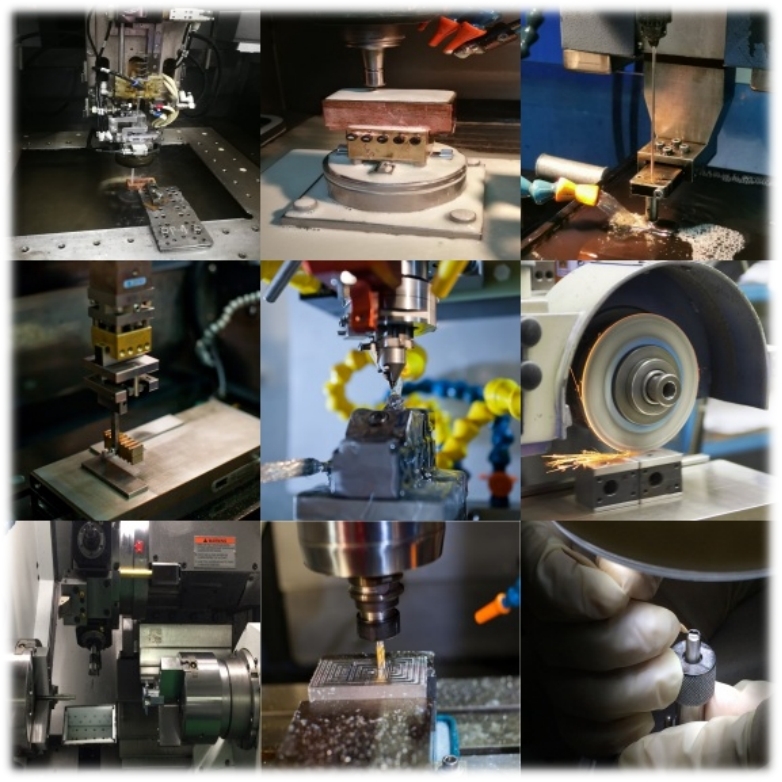

At Rigid Group of Companies, our machining services cater to a broad spectrum of part requirements. Whether it's crafting a new spare part or modifying an existing one, we have you covered. We excel in fabricating high-precision tooling parts with an accuracy of 3µ and high-precision CNC machined parts with an accuracy of 10µ, all based on customers' mechanical drawings (GD&T) to meet specific requirements.

In addition to our precise material machining capabilities, we offer valuable supplementary services. These include secondary processes, press tool assembly, laser marking, and engraving. Opting for these secondary processes after material finishing can save you time. We seamlessly integrate these services with the materials that have completed machining, utilizing our ISO 9001 certified service partners when needed. These services are an integral part of our systematic production line, ensuring that we meet your specification requirements in accordance with the drawings provided by our valued customers.

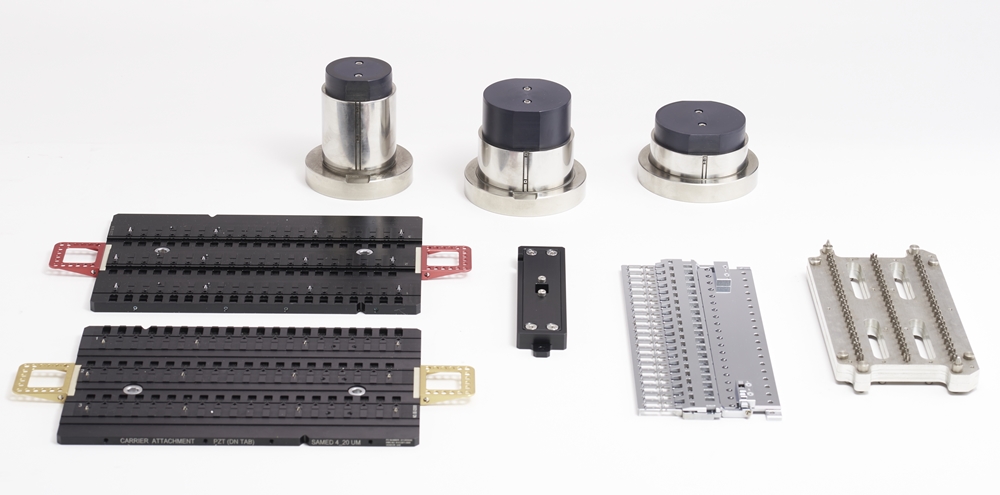

In the Sub-Mechanical Assembly section, we orchestrate the perfect fit of mechanical parts. Our spare parts (mechanical parts) are carefully fabricated in-house in our production area. For standard parts, we collaborate with trusted suppliers, following the instructions outlined in the Bill of Materials (BOM) from the mechanical drawings. It's precision assembly at its finest.